Did You Know?

The market for retaining walls is huge and accounts for billions of dollars every year!

- Most retaining walls are composed of concrete.

- Way more that half of all those concrete retaining walls are built with modular blocks.

- The largest percentage of those walls are 5′ and under!

I have been in this market for over 30 years and have seen many changes but few have addressed the environmental impact (or lack of it) of typical concrete retaining wall blocks.

My first patent was for a plantable retaining wall block over 30 years ago. It was ahead of its time here in the U.S. and not much has changed since then. I love the market and have stayed in and around it for my entire career, mostly due to the work I have been able to produce in the plantable wall market. Plant covered retaining walls are so cool to be around and they create green-space, habitat, urban cooling and positive environmental service. Positive benefits that would not be present with a typical concrete block wall. (Click here for a 30 second overview)

Check out one of our previous blog posts on this topic for additional information.

Vertical Gardening Niche’s:

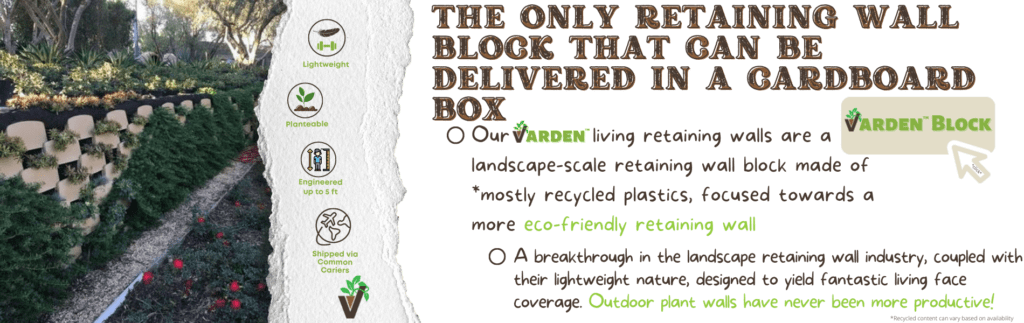

All of our work and products fit under the heading of Living Walls and we prefer to call them all Vertical Gardens. Our retaining walls are not totally vertical, but with 20 degrees of setback from vertical can be gardens of cut flowers, native perennials, edible plants or vines and groundcovers. The later has been used more than any other planting preference due to the need to reduce maintenance where walls will not be tended on a regular basis. Sedum (a succulent groundcover) of several varieties and many types of vines will totally cover the blocks face in a season to make the structure disappear. That has been my favorite treatment but it’s hard to take pictures for showing off, because nobody can see what the structure is behind the plants making it all possible.

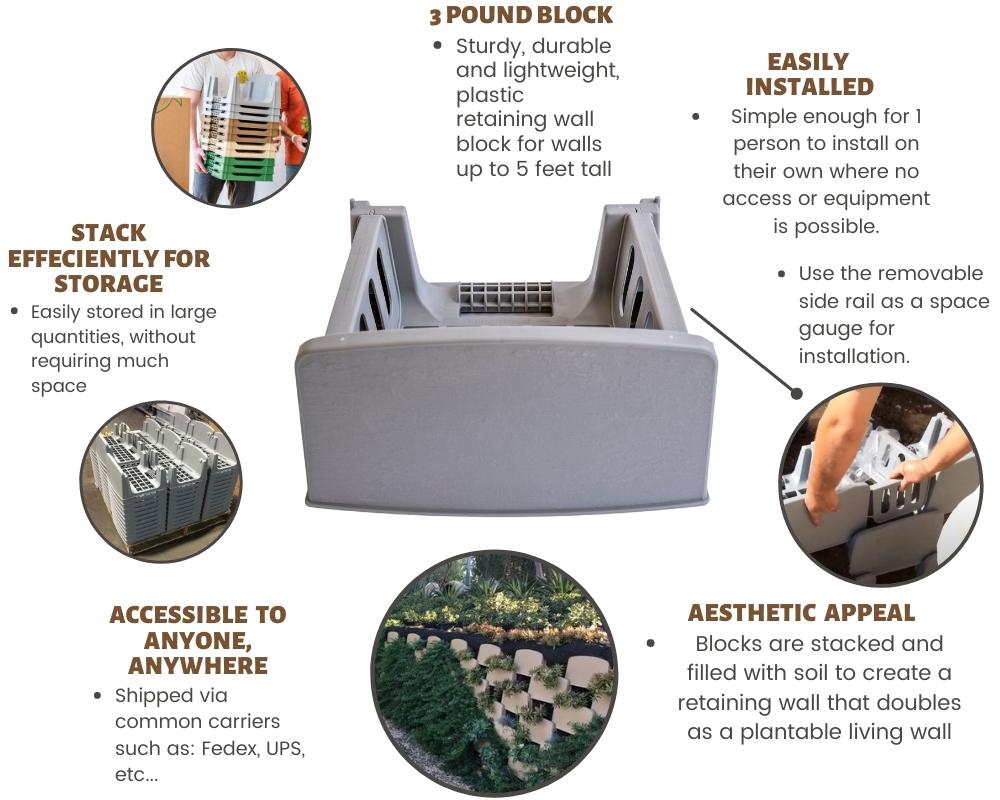

Varden P100 Blocks:

My early concrete blocks, that were plantable, enabled many fantastic living retaining walls over the past 30+ years. Since they were concrete they were heavy, which made shipping and handling a costly part of their use. We designed the Varden P100 system to be made of tough plastic and to last just about forever. It makes sense to use as much re-processed and recycled plastic as possible, and then bury it in the ground for a long lasting task such as a retaining wall. Their light weight makes them easy to handle and shippable. In fact we know of no other block capable of building landscape walls up to 5′ tall, that can be shipped by UPS and FedEx right to a customer’s door!

Here is a link to one of our curated playlists on YouTube with plenty of Varden Block info.

I have always been in love with the environmental service offered by living retaining walls. Filling the pocket of each block with local compost makes a huge positive impact when multiplied by all the blocks it takes to build a wall. All that carbon that is prevented from going to the landfill can now be beneficially re-used in a beautiful and needed structure. It’s a great offset and no concrete block system can provide this level of quantifiable service. Seeing the outcome and watching vibrant plants living in and on the structure is what gets me fired up. This beneficial trend is catching on!